Machines

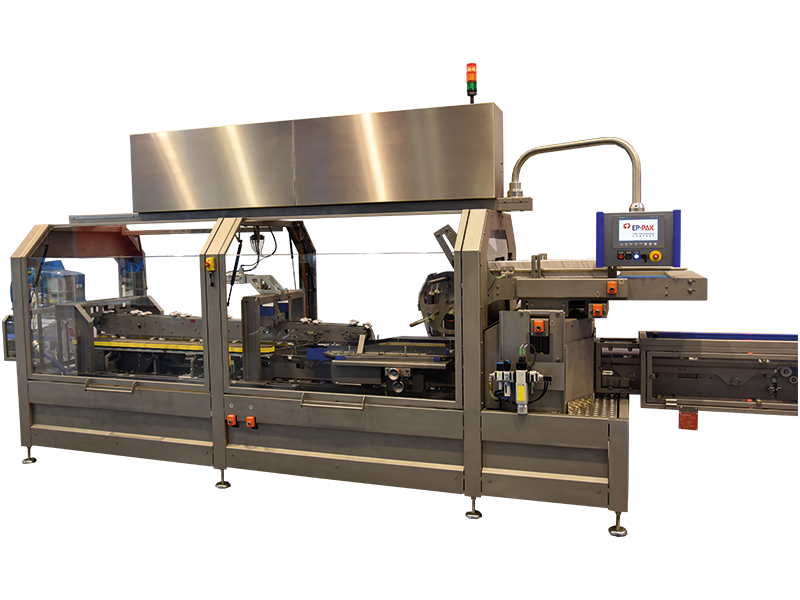

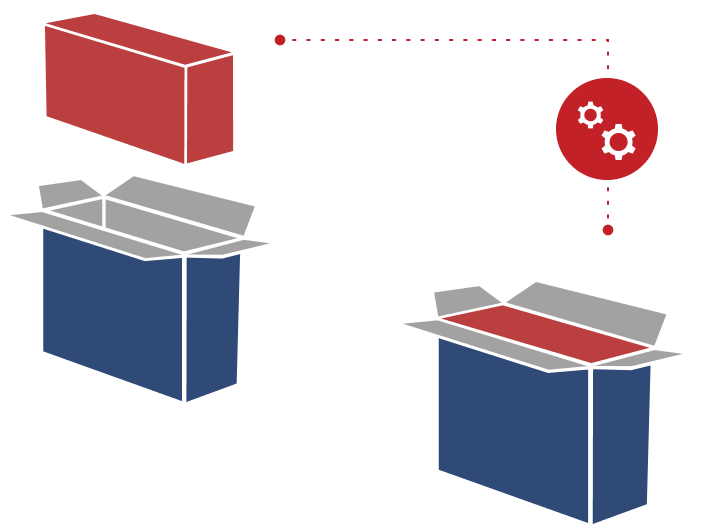

CARTON FORMER

The technical, practice-oriented concept of our carton forming machines offers a wide range of possible applications both as individual machines and as machines within packaging lines. Our machines are customized to different requirements, formats and performances and therefore represent a high level of flexibility.

The EP-PAK carton former forms flat carton blanks of different designs and carton structures into cartons – with and without lids. The formed carton falls through the tool chute onto the downstream conveyor system. The flat carton blanks are formed in the machine by means of forming tools suitable to the carton blank design.

Request quote

Available models

Available tools

Advantages

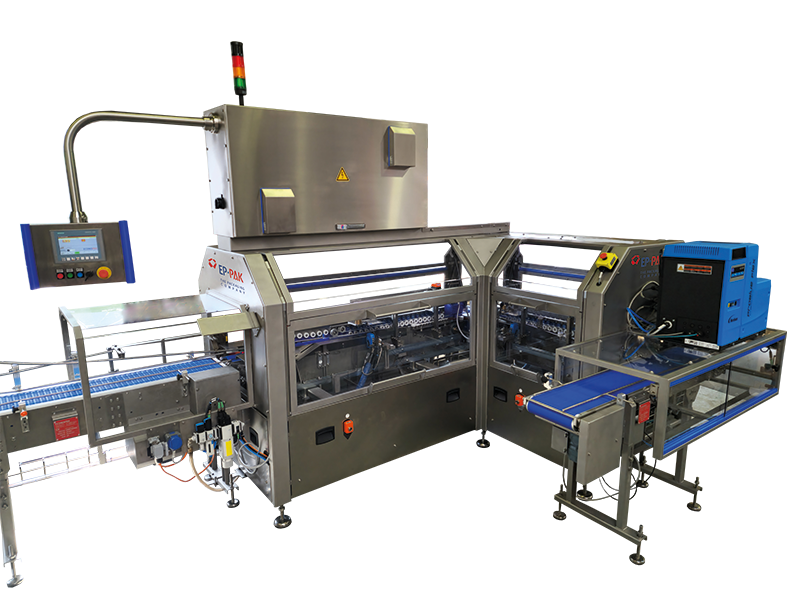

CARTON CLOSER

The EP-PAK carton closer closes filled cartons made of coated or uncoated cardboard, as well as corrugated board, in various qualities. The cartons are closed with hot-glue or hot- air. After an individual consultation we will decide whether our standard machines meet your technical requirements. You can choose between single-flap carton closer, straightline carton closer, angle carton closer or high-performance carton closer.

Special customer requirements are taken into account in the machine designs. Our carton closers offer highest flexibility. Different closing options can be processed on the machines. Single flap lock system, triple flap lock system or stack-in flap lock system etc.

Request quote

Available models

Advantages

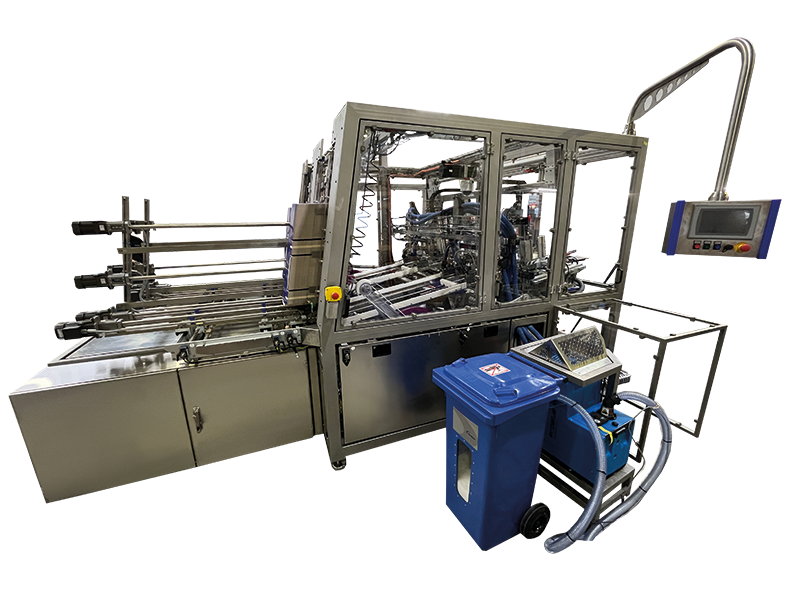

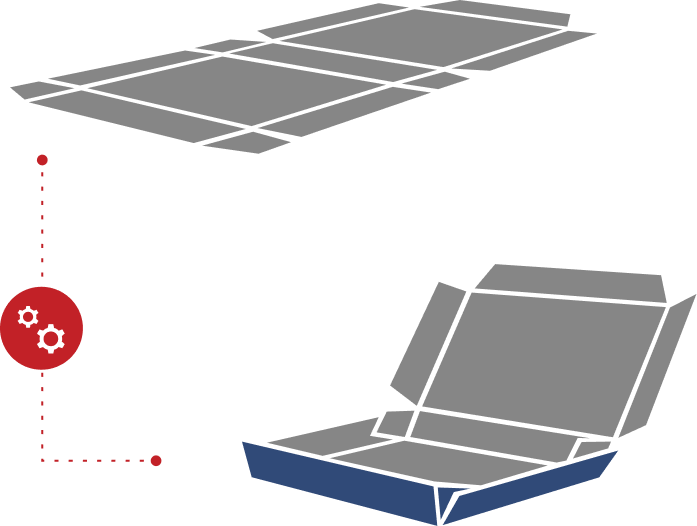

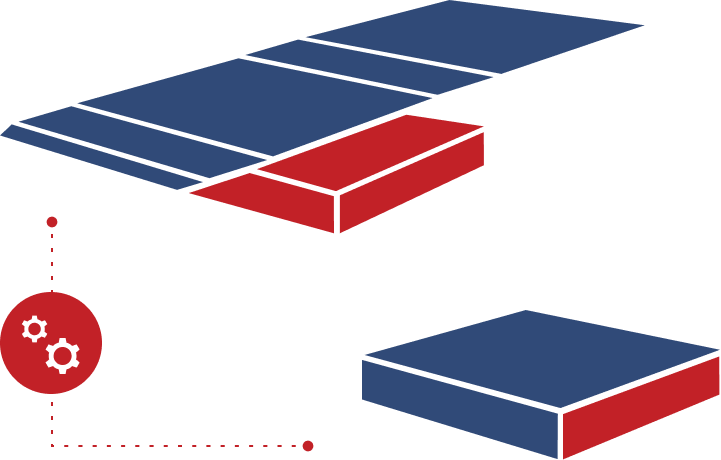

SIDE LOAD CARTONER

The EP-PAK cartoner is used for the automatic forming, filling and closing of pre-glued carton blanks made of plastic-coated or uncoated cardboard. High operating comfort, fast and reproducible format changeover with well-proven technology have turned the cartoner into an economical investment. The large format range covers many packagings from various product groups.

Request quote

Available models

Available tools

Advantages

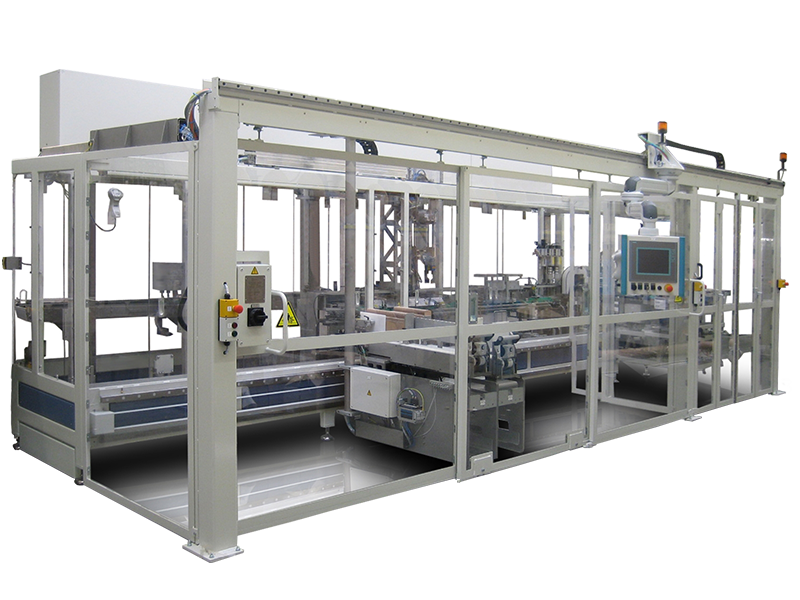

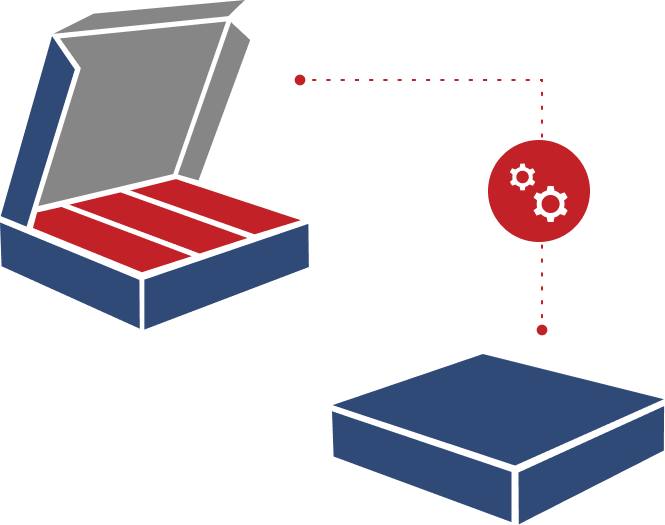

TOP LOAD CARTONER

The vertical cartoner is designed for different products and their variations and processes carton blanks made of full- and corrugated cardboard with double-sided stack-in locking system. The intermittently working cartoner fills pre-glued cartons from above.

The new vertical cartoner solution represents a new machine generation that combines several machine types and steps in the packaging process in one machine.

Request quote

Available models

Available tools

Advantages

SLEEVER

The carton blank construction of the sleeves is designed with the gluing flap on the lower side (inside). Together with our development & design department, an individual sleeve machine concept is created according to the customer requirements. The sleeve packaging offers optimal presentation possibilities for the products of our customers, with economic use of materials and attractive design at the same time.

Request quote

Available models

Available tools

Advantages

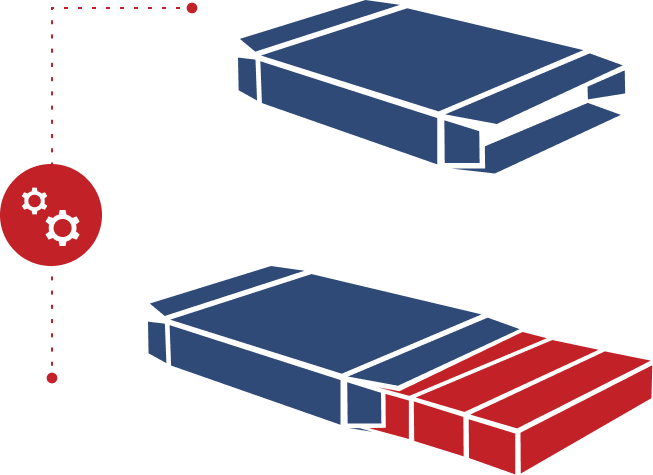

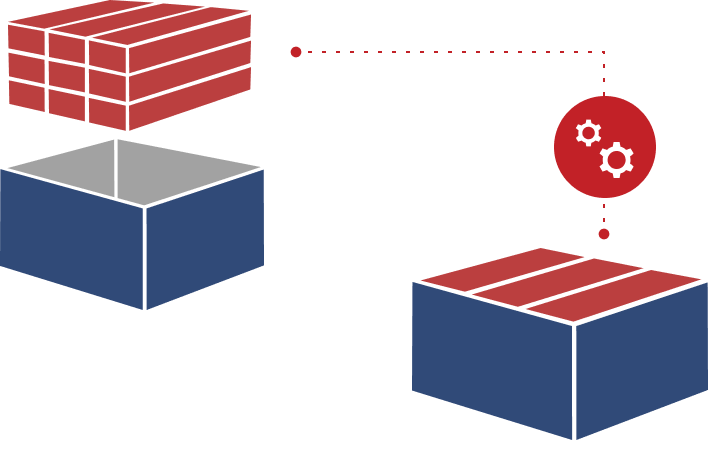

CASE PACKER

The EP-PAK case packer handles the packaging of different product groups. These can be either solid forms (cartons) or flexible products (bags).

The flat, not pre-glued carton blanks are taken off the magazine and erected to a U-shape. The products are received according to customer specifications, formed and pre-grouped by means of a timing chain or stacking unit. The formed group of products is pushed into the erected carton sideways. The outer carton is glued and pushed out of the machine.

Both tray carton blanks and wrap-around carton blanks can be processed. The adhesive flap can be positioned on the outside or inside.

Request quote

Available models

Available tools

Advantages

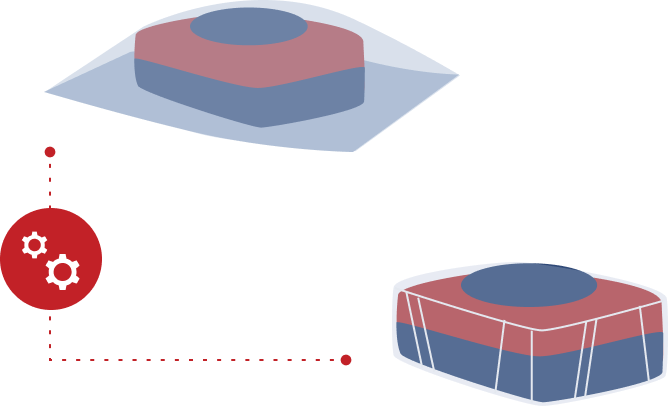

SHRINKER

The shrinker is used for shrinking water-soluble film onto tabs. Taking over the tabs directly after the flowpacker, capable of shrinking up to 1200 tabs per minute. EP-PAK takes over the tabs with 2 side belts above the customer’s conveyor, presses and guides the tabs into the shrinker in a controlled manner. The shrinker has 3 heating zones, left / right and top, the electric heaters work according to the counterflow principle. The protective enclosure is made of stainless-steel grids. In case of a stop or emergency, the side belts and heaters go into a safe position. Lateral belts at the exit zone press the heated film around the tab. The exit belt with pneumatic ejection and blast air ejection is located under the two side belts. To cool down the temperature of the film, the blower uses the room air in the factory.

Request quote

Available models

SECOND HAND

EP-PAK machines are very robust and of high quality. This makes them a long term invest. Nevertheless, sometimes they are no longer needed in production and EP-PAK repurchases them for refurbishment and reselling as a second-hand machine. Ask about the current availability of those machines.

Request quote